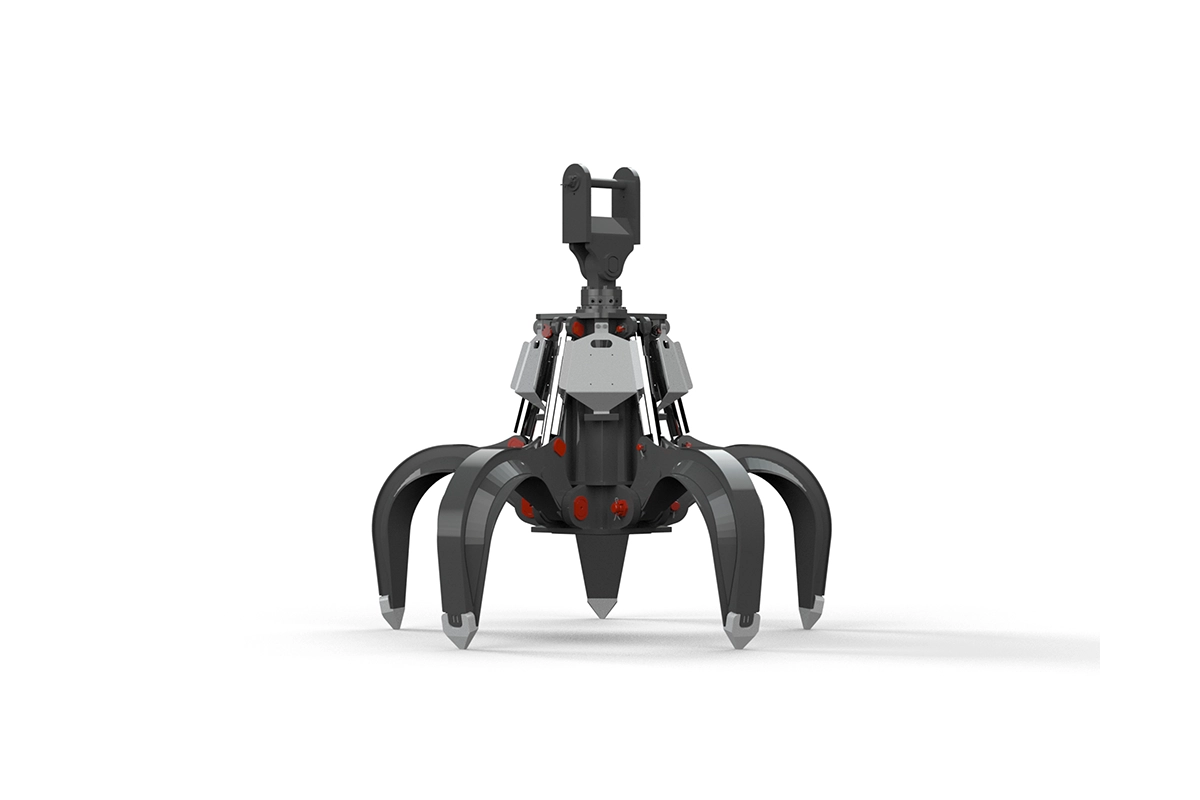

Grabs

Product Description

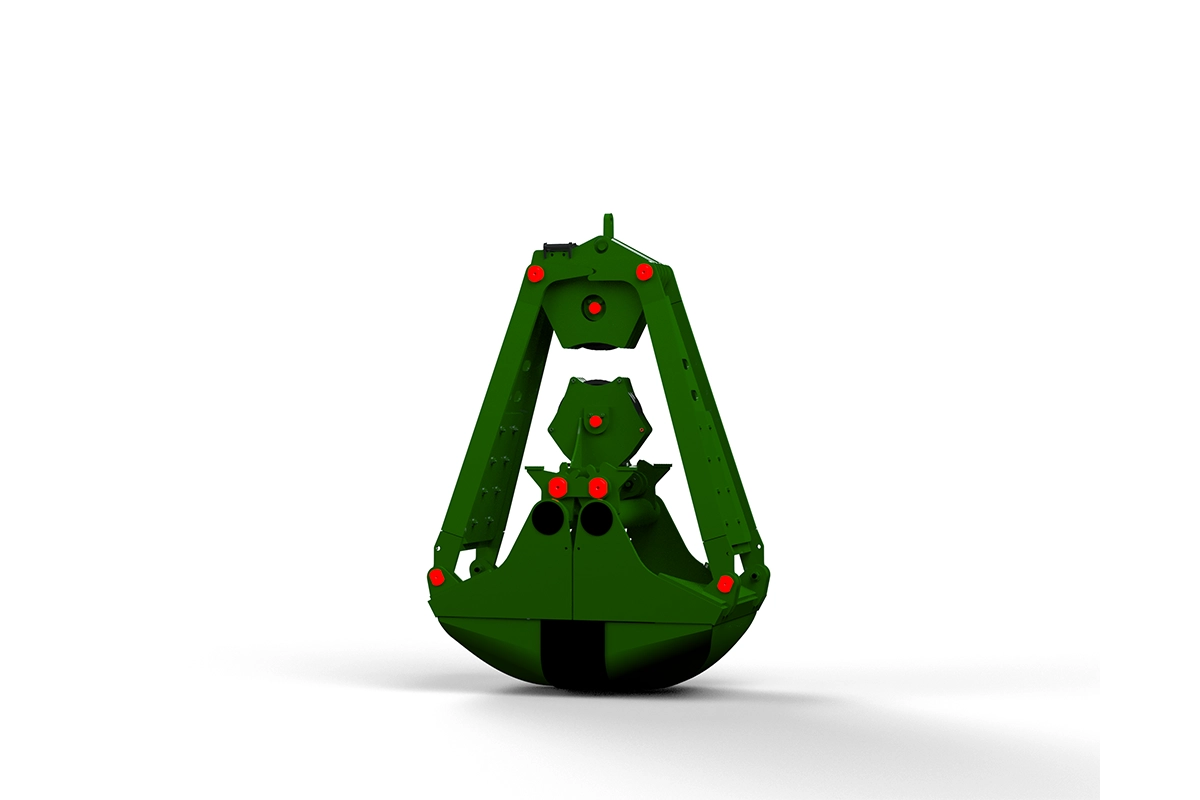

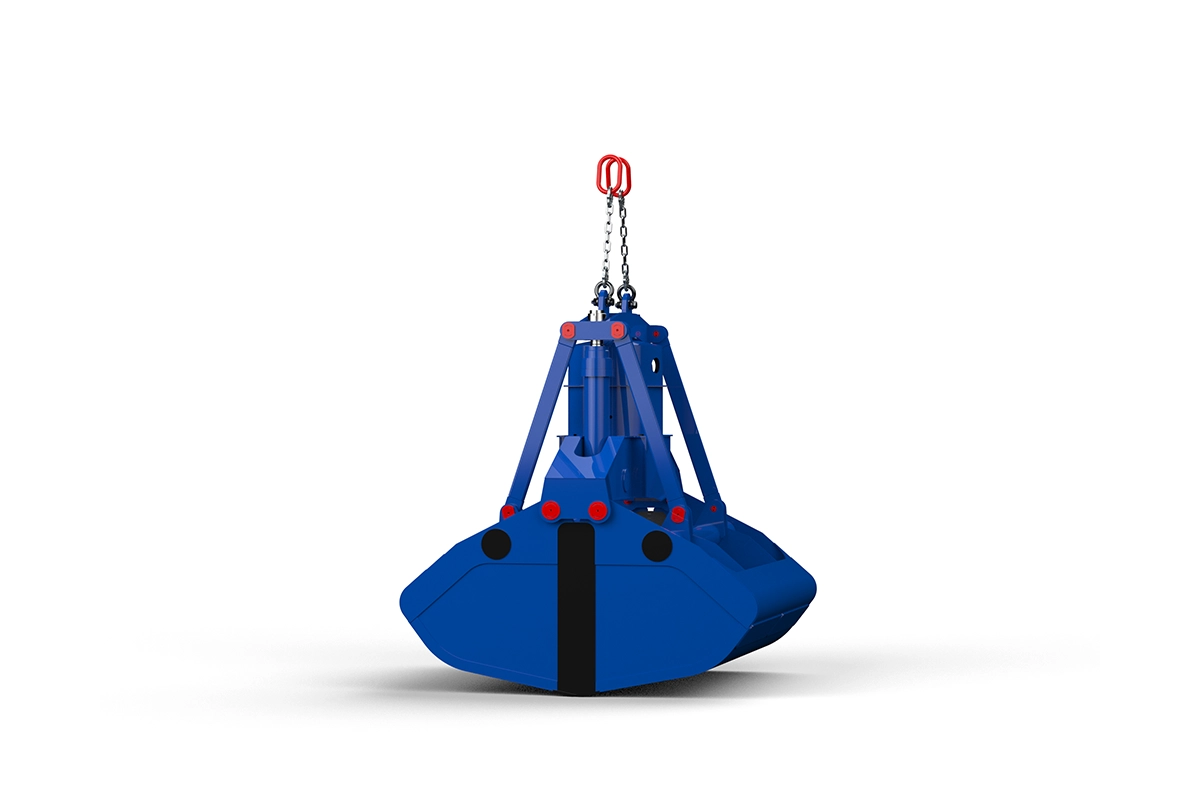

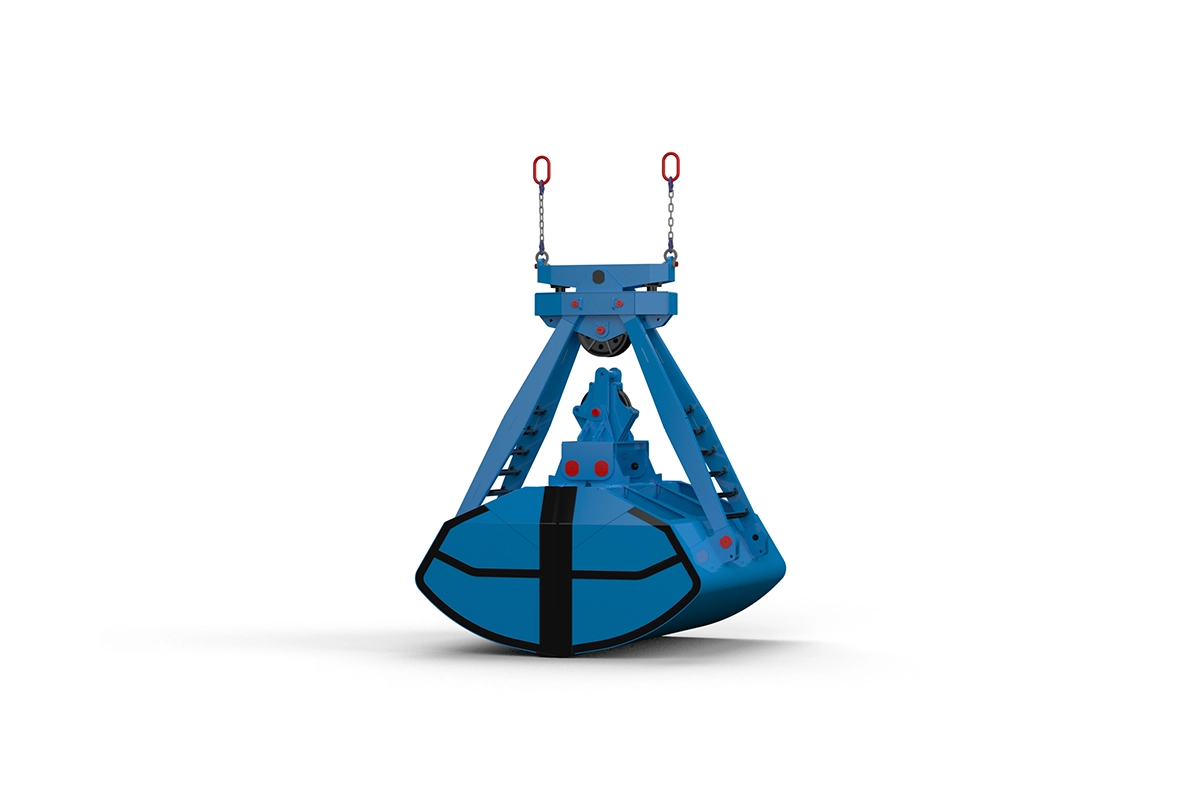

GUVEN®️ Dredging facility grabs enable handling of bulk materials on dredging progress together with mobile harbour cranes, excavator machines, floating, crawler, 2 roped and 4 roped cranes. We offer a wide range of clamshell and orange peel grabs for various applications and for materials of different weights, such as sand, clay, gravel, rocks, and etc. We also manufacture attachments that are customized for customer specific needs.

The selection of GUVEN® Dredging Facility Grabs should be based on the type of available equipment and operational conditions. These grabs are available in both mechanical and hydraulic versions to suit various requirements.

GUVEN® provides worldwide service network.

Features

Constructions Material Selection

Choosing the appropriate material with excellent wear resistance and high-strength steel guarantees optimal performance throughout the product’s lifecycle, providing long-term value to clients.

Wear Resistance Special Steels

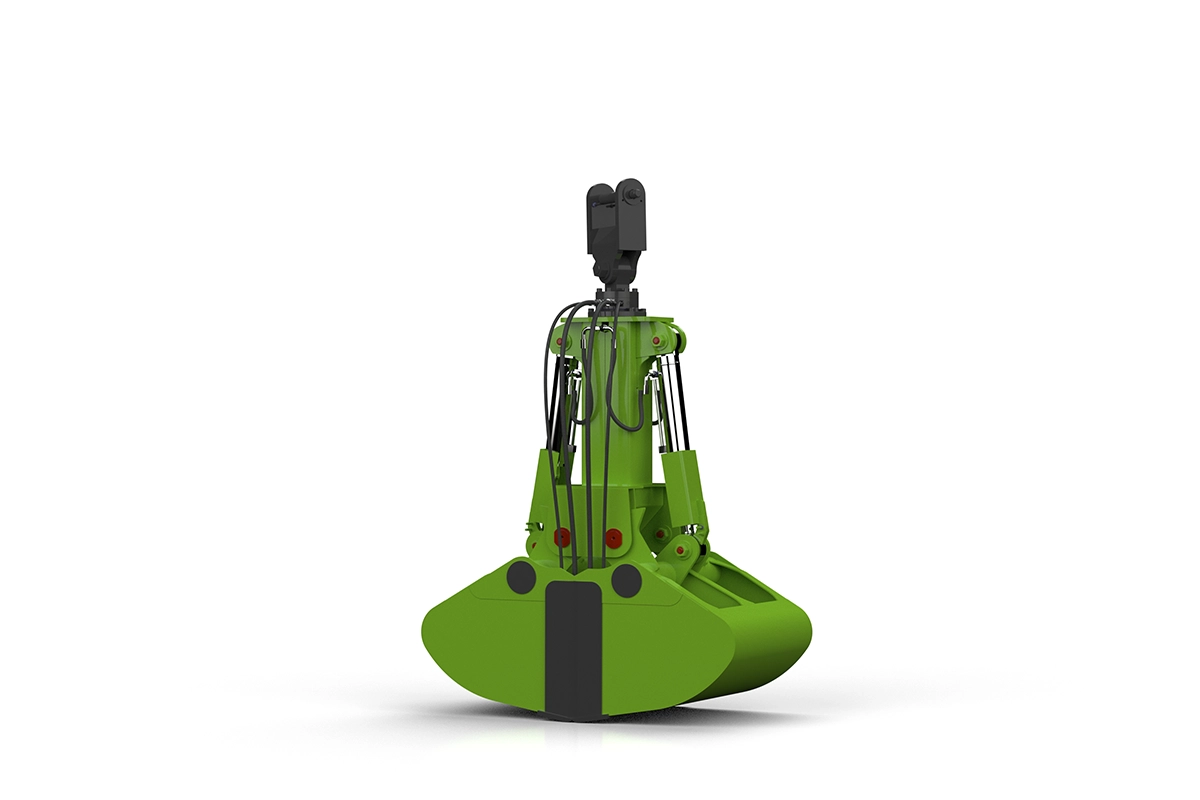

Guven Grabs feature lips made from high quality 500Hb Swedish steel, offering exceptional wear resistance to be leakage proof

Varieties of Bucket or Tine Designs

Enclosed and open designs are available and can be selected based on operational conditions to enhance productivity and improve pickup efficiency.

Teethes for Digging Cargo

With bolt-on extension shafts and digging teeth to increase digging depth of the grabs.

Lifting Points to Transfer Machines

The lifting points are strategically located at the grabs to transfer machines together with grabs onto cargo hall.

FAQ

Understanding the weight and type of material you’re handling, along with the capabilities of your crane or hoisting equipment, will help you determine the best grab size. Various capacities are available in our manufacturing with volumetric capacity from 3 cubic meter to 30 cubic meter.

Mobile harbour cranes, excavator machines, floating, crawler, 2 roped and 4 roped cranes.

A mechanical grab operates using a wire system powered by the crane, while a hydraulic grab is operated by hydraulic force, which is supplied through hydraulic hoses connected to a hydraulic power unit or excavator.

The choice is entirely dependent on the crane or machine with which the grab will be paired.

Dredging facility grabs are specialized types of grabs or clamshell buckets used in dredging operations. Dredging involves the removal of sediment, sand, mud, and other materials from the bottom of water bodies such as rivers, harbors, or seas, typically to maintain navigable waterways or to reclaim land.