Grabs

Product Description

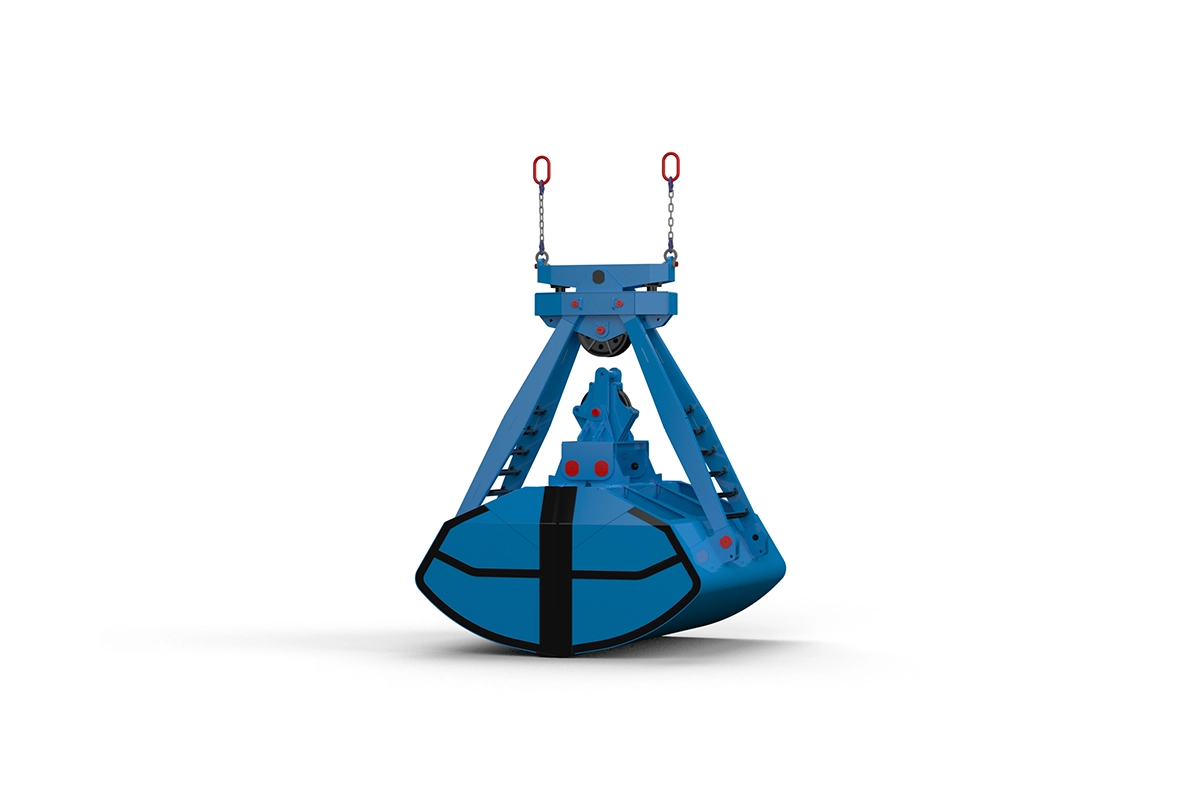

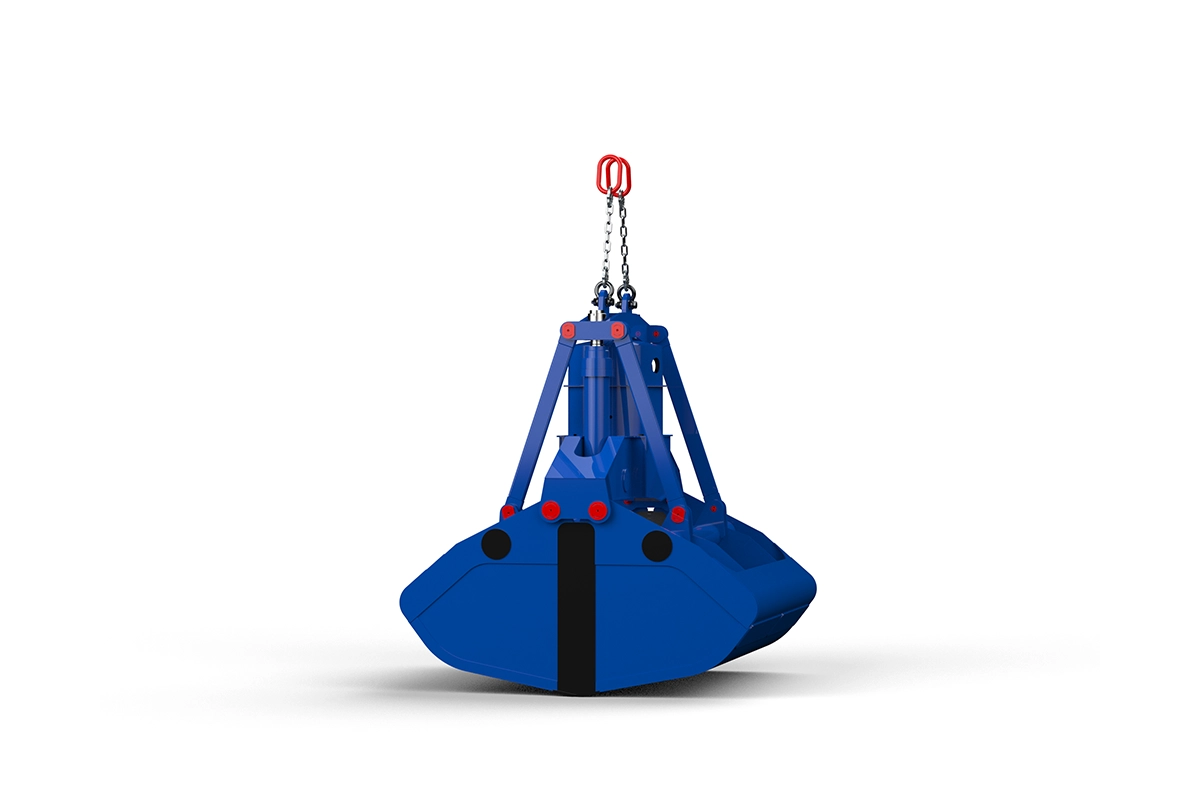

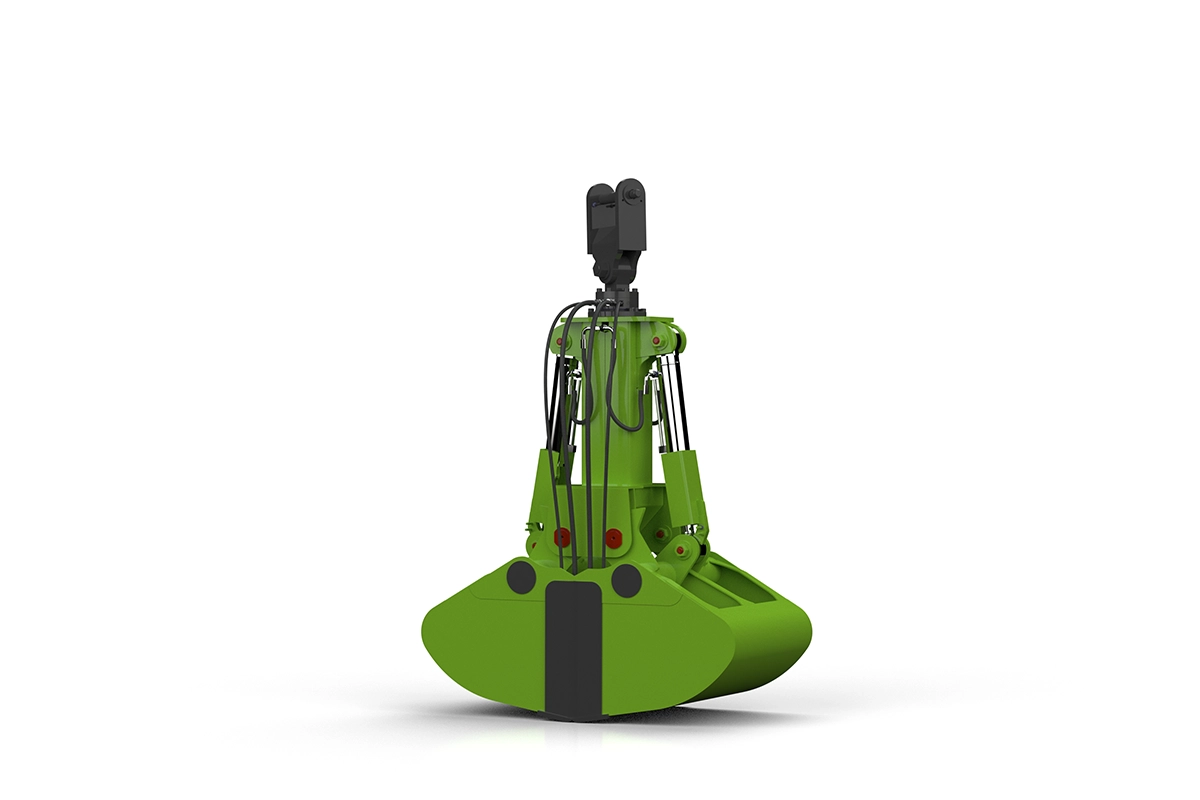

GUVEN®️ Mechanical clamshell rope operated grabs enable the most efficient handling of bulk materials together with mobile harbour cranes, floating, transhipment, crawler and 4 roped ship cranes. We offer a wide range of clamshell grabs for various applications and for materials of different weights, such as grain, gravel, soya, clinker, coal, pebbles, sand, fertilizers, wood chips, nickel ore, bauxite, iron ore, iron pellets, metal ores, aggregates, gypsum, biomass and etc. We also manufacture attachments that are customized for customer specific needs.

GUVEN® Mechanical Clamshell Buckets can be operated manually on cranes with benefits of dual drum wire systems.

With Guven Grab you have the upper hand in improving the entire cargo handling progress efficient and reliable by 2 roped or 4 roped cranes opening and closing on the air and floor.

GUVEN® provides worldwide service network.

Features

Working System

Ropes 1 and 2 control the opening and closing of the grab to securely hold the material, while Ropes 3 and 4 are used to lift and position the grab, after which the buckets can be opened to release the material.

Perfect Matching of Sheaves

The number of sheaves is chosen based on operational conditions to optimize productivity and pickup capability, with pulleys guiding the ropes for precise control of the grab’s movements.

Varieties of Bucket Designs

Enclosed and open designs are available and can be selected based on operational conditions to enhance productivity and improve pickup efficiency.

Easy Installation and Fitting

Possible to use any type of crane Always ready to use with all accessories. NO need additional accessories like cable drum system or chain. Connect to hook of crane and work with immediately

Less Maintenance

Simple and basic system together with lubrications channels.

Lifting Points to Transfer Machines

The lifting points are strategically located at the grabs to transfer machines together with grabs onto cargo hall.

Wear Resistance Special Steels

Guven Grabs feature lips made from high quality 500Hb Swedish steel, offering exceptional wear resistance to be leakage proof

Equipped with High Quality Wire Ropes

Equipped with Kiswire Hyfil K8 Compact long service life wire roped.

Optional Equipment

Stowage on Board of Vessel

Provides foundations and lashing materials to storage of grabs on board of vessel.

Easy to Carry by Forklift

Preparing places for forklift forks in order to carry easily in Ports & Terminals.

Parking Platform

Parking platform can help users for secure better.

Central Lubrication System

A central lubrication system on grabs automatically distributes lubricant with putting lubrication on one point to all critical moving parts, ensuring smooth operation, reducing wear and tear, and minimizing maintenance costs.

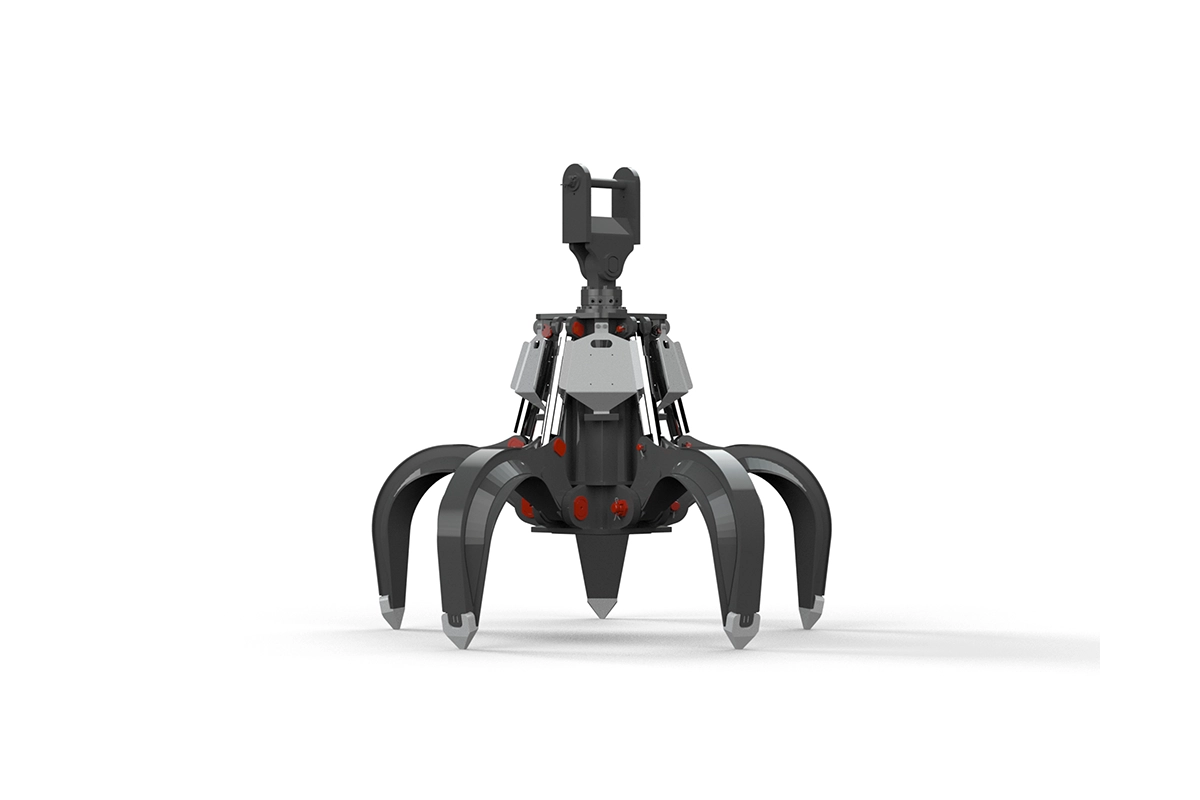

Teethes for Digging Cargo

With bolt-on extension shafts and digging teeth to increase digging depth of the grabs.

Bolted Design Wear Resistance Special Steels

With bolt-on cutting edge bucket lips to simplify replacement of lips

FAQ

Understanding the weight and type of material you’re handling, along with the capabilities of your crane or hoisting equipment, will help you determine the best grab size. Various capacities are available in our manufacturing with volumetric capacity from 2 cubic meter to 60 cubic meter.

Harbour cranes, floating, transhipment, crawler and 4 roped ship cranes.

Both dual winch system, but depending on crane type 2 roped and 4 roped versions are available.

Shipping and Maritime Operations & Ports and Terminals & Transhipment & Harbors & construction sites

A mechanical 2-roped and 4-roped grabs area type of bulk handling equipment that uses dual winch cranes to control the opening and closing of the grab’s buckets. It is used for lifting and transferring bulk materials like coal, ore, grain, gravel, etc..